75 Jahre Erfahrung in mechanischen und thermischen Kunststoffverarbeitungsverfahren.

Wir nutzen ein mannigfaltiges Spektrum an Verfahren zur Kunststoff- und Verbundstoffverarbeitung, um für Sie das optimale Endergebnis zu erreichen.

CNC Fräsen in der Kunststoffverarbeitung

Fräsmaschinentechnologie mit bis zu 5-Achsen gewährleisten eine maximale Toleranzgenauigkeit und Flexibilität in der Formgebung Ihrer (auch komplexen) Bauteile. In Verbindung mit unserer verschnittoptimierten CNC-Prozesssteuerung und dem Einsatz von Diamantwerkzeugen erhalten Sie das optimale Ergebnis aus Qualität und Kosteneffizient, passend zu Ihren Ansprüchen.

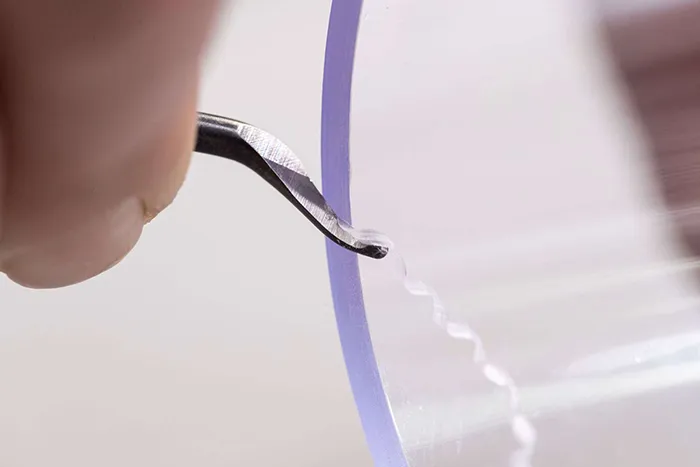

Lasern in der Kunststoffverarbeitung

Aufgrund von kurzen Umrüstzeiten, der ökonomischen Belegung des Werkstoffes und tendenziell schnellen Fertigungszeiten ist das Laserschneiden das perfekte Verfahren, um auch Kleinserien sehr wirtschaftlich und qualitativ hochwertig zu fertigen. So kann beispielsweise ein nachträgliches Finishing aufgrund hochpräziser Kanten oftmals vollständig entfallen.

Biegen und Kanten in der Kunststoffverarbeitung

Speziell beim Kanten und Biegen ist die Kombination aus menschlicher Expertise und einem State-of-the-Art Maschinenpark gefragt. Infrarot- und Drahtbiegeanlagen, Einzel- bis Mehrfachbiegung mit variablem Radius sowie Kantmaschinen kommen bei uns zum Einsatz, um Ihre Teile bzw. Baugruppen in reproduzierbarer Qualität und gemäß Ihren Wünschen zu fertigen.

Warmformen/Thermoformen in der Kunststoffverarbeitung

Basierend auf unserer jahrzehntelangen Erfahrung ist das Warmformen eine unserer Kernkompetenzen. Zeitgesteuerte Temperöfen gewährleisten eine spannungsarme Umsetzung. Gemäß Ihrer Anforderungen an Qualität und Stückzahl wählen wir das ideale Form- und Serienwerkzeug aus, um Ihre Bauteile effizient und hochwertig zu fertigen.

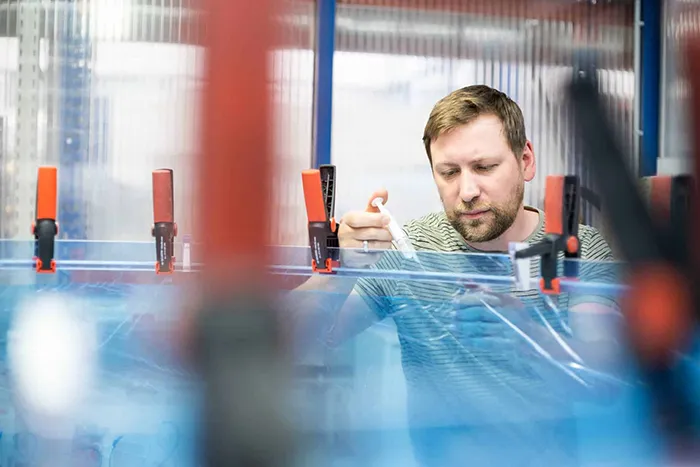

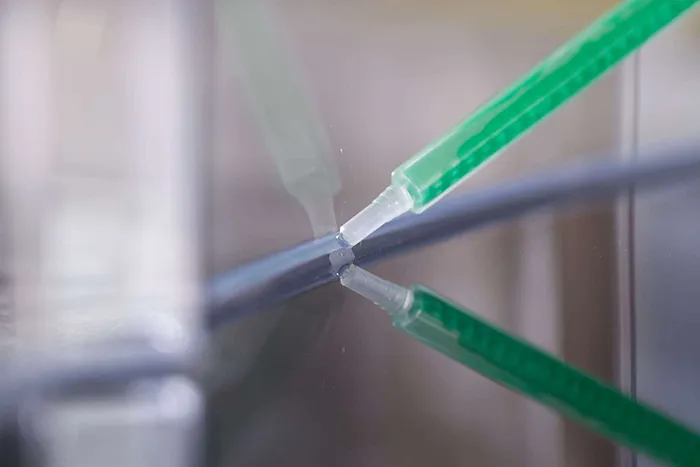

Kleben in der Kunststoffverarbeitung

Einzusetzende Klebstoffe bzw. Klebstoffrezepturen und Kunststoffe sind immer in Abhängigkeit voneinander und der späteren Nutzung des Bauteils zu betrachten. Unsere jahrzehntelang verbesserten – und zum Teil auch sehr wohlbehüteten – Klebstoffrezepturen, welche individuell nach Erfordernis zum Einsatz kommen, führen zum optimalen Ergebnis und erschaffen ein möglichst langlebiges Bauteil für Sie.

Tiefziehen in der Kunststoffverarbeitung

Tiefziehen ist ein unglaublich vielseitiges Verfahren. In unserem Maschinenpark findet sich ein breitgefächertes Portfolio an Tiefziehmaschinen und professionelle Möglichkeiten zur Nachbearbeitung für die unterschiedlichsten Bauteile und Stückzahlen. Mit unserem eigenen Formenbau stimmen wir die Werkzeugart und Form exakt auf Ihr Bauteil ab.

Unser Maschinenpark bei Keim Kunststoffe

Modern, innovativ, effizient. Unser Trumpf. Ihr Vorteil.

Wir setzen auf Hightech in der Fertigung! Von der Fräse über Laserschneider über Temperöfen bis hin zum Thermoforming – unsere gesamte Fertigung befindet sich auf dem modernsten Stand.

Aber das ist nicht alles: Oftmals sorgt das “schwächste” Glied in einer Kette für die größte Verzögerung im Fertigungsprozess. Aus diesem Grund haben wir das perfekte Zusammenspiel aus vollautomatischer Lagerhaltung, flexiblen Maschinen- und Anlagenmanagement sowie Just-in-time Auslieferungsprozessen etabliert und optimieren dieses ganze Gebilde sukzessive.